To true a dirt bike wheel, you can follow these steps: 1. Remove the tire and tube from the wheel.

2. Use a spoke wrench to adjust the tension of the spokes, tightening or loosening as necessary.

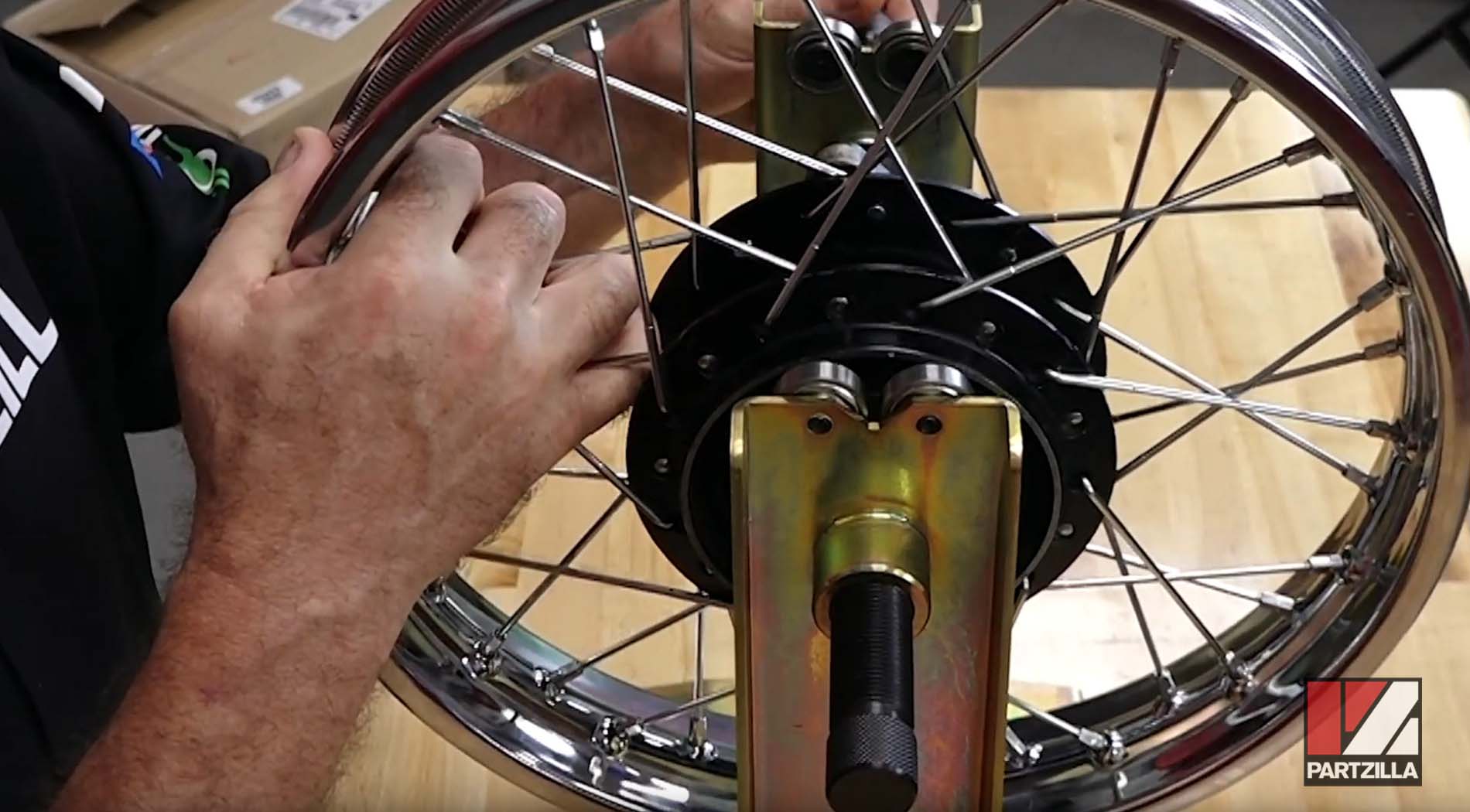

Credit: www.partzilla.com

Understanding Wheel Truing

Wheel truing is a vital maintenance task for dirt bike riders. It involves adjusting the spokes and rim to ensure the wheel spins straight and true. Knowing how to true a dirt bike wheel can prevent accidents, improve performance, and increase overall riding enjoyment.

So, what exactly is wheel truing? Put simply, wheel truing is the process of aligning the rim and spokes to eliminate any wobbles or misalignments. When a dirt bike wheel is properly trued, it enhances stability, reduces vibrations, and optimizes power transfer.

Understanding the importance of wheel truing is crucial for every dirt bike enthusiast. An out-of-true wheel can lead to a range of issues, including compromised handling, increased wear on tires, and even damage to the bike’s components. By regularly truing the wheels, riders can maximize safety and performance on the trail.

Recognizing the signs of an out-of-true dirt bike wheel is also key. Common indicators include visible wobbles, unusual vibrations, and inconsistent tire wear. If any of these signs are noticed, it’s essential to address the issue promptly to prevent further damage to both the bike and the rider.

Tools And Equipment Needed

Truing a dirt bike wheel requires a few essential tools and equipment to ensure a smooth and effective process. These tools include a spoke wrench, which is used to adjust the tension of the spokes, and a truing stand. The truing stand provides a stable platform for the wheel while allowing you to identify any misalignments.

A nipple driver helps in tightening or loosening the nipples that connect the spokes to the rim. Additionally, a dishing tool is employed to measure the alignment of the wheel, ensuring it is centered. Lastly, a tension meter is handy to measure the tension applied to the spokes, ensuring even tension throughout the wheel. Having these tools at your disposal will make the process of truing a dirt bike wheel more efficient and effective.

How to True a Dirt Bike Wheel: Step by Step Guide

Preparing For Wheel Truing

When truing the wheel of your dirt bike, there are a few key steps to take beforehand.

- Removing the wheel from the bike: Begin by jacking up the bike and removing the axle nut and washers. Make sure to support the bike securely before taking off the wheel.

- Securing the wheel in the truing stand: Once the wheel is removed, carefully place it in a truing stand to hold it steady during the process. Ensure that the stand is stable and properly adjusted for the wheel size.

- Inspecting the wheel for damage or loose spokes: Before starting the truing process, visually inspect the wheel for any signs of damage such as bends or cracks. Also check for loose spokes or nipples that might need tightening.

By following these steps, you will be well-prepared to true your dirt bike wheel effectively and ensure optimal performance during your rides.

Truing The Rim

Truing the rim of a dirt bike wheel involves identifying high spots and low spots on the rim and adjusting spoke tension to move the rim toward the center. This can be done effectively using a truing stand as a guide. The first step is to carefully spin the wheel and observe any wobbles or deviations.

By gently tapping the rim with a rubber mallet, high spots can be identified as areas that cause the wheel to move off-center. Low spots, on the other hand, can be detected by observing areas where the wheel slightly dips. Adjusting the spoke tension on the affected areas can help move the rim towards the center and eliminate any wobbles. Using the truing stand, the rim can be aligned accurately by adjusting each spoke incrementally until the desired trueness is achieved.

Checking Wheel Alignment

When it comes to checking wheel alignment on a dirt bike, using a dishing tool can be very helpful. The dishing tool allows you to determine if the wheel is true or if it needs adjustment. By placing the tool against the rim, you can see if the wheel is centered or if it is leaning to one side. Adjusting spoke tension is another way to ensure that the wheel is centered in the frame. By tightening or loosening the spokes, you can bring the wheel back into alignment. It’s important to regularly check and true the dirt bike wheel to ensure optimal performance and prevent any issues while riding.

Achieving Proper Spoke Tension

In achieving proper spoke tension for a dirt bike wheel, a tension meter can be used to measure the tension of the spokes. This tool helps ensure that the spokes are tightened evenly, resulting in a strong and well-balanced wheel. Adjusting the spoke tension is essential to achieve an even tension throughout the wheel. By carefully tightening or loosening the spokes, you can eliminate any inconsistencies in tension, which can lead to wheel misalignment and future issues.

Checking The Spoke Tension

When **truing a dirt bike wheel**, one important step is **checking the spoke tension**. This can be done by **tapping the spokes to listen for even tension**. Start by tapping each spoke with a spoke wrench or a small metal object. A well-tensioned spoke will emit a clear, high-pitched sound, while a loose spoke will produce a dull thud. Make sure to tap all the spokes on both sides of the wheel, paying attention to any significant differences in sound.

If you notice any spokes that sound loose, you can make **minor adjustments to individual spokes** to true the wheel. Use the spoke wrench to tighten the loose spoke by turning it clockwise. It is important to make small adjustments and check the tension after each turn to avoid over-tightening. Repeat this process for any other loose spokes until the wheel is properly tensioned.

By carefully checking the spoke tension and making necessary adjustments, you can ensure that your dirt bike wheel is true and ready for smooth and safe riding.

| Steps to True a Dirt Bike Wheel |

|---|

| 1. Checking the Spoke Tension |

| 2. Tapping the spokes to listen for even tension |

| 3. Making minor adjustments to individual spokes as necessary |

Finalizing The Truing Process

After adjusting the spokes and achieving proper alignment, it’s crucial to double-check the dirt bike wheel for any remaining issues. Check for any loose or over-tightened spokes by gently tapping the spokes with a spoke wrench. Ensure that all the spokes have equal tension by plucking them lightly. If there are any loose or unbalanced spokes, adjust them accordingly using the spoke wrench.

Once you are confident that the wheel is properly trued, it’s time to reinstall it onto the dirt bike. Align the wheel with the fork or swingarm, making sure the axle aligns perfectly with the dropouts. Insert the axle and tighten the nuts or bolts to secure the wheel in place.

To ensure optimal performance, conduct a thorough test ride. Pay attention to any wobbling or vibrations during acceleration and braking. Ensure that the wheel spins freely without rubbing against the brake pads or any other bike components. If any issues are detected, revisit the truing process and make necessary adjustments until the wheel operates flawlessly.

Maintenance Tips To Prevent Wheel Truing

Regularly inspecting the spokes for loose or damaged ones is crucial to maintaining the trueness of your dirt bike wheel. Any worn out or broken spokes should be replaced promptly to avoid further damage. In addition, it’s important to avoid harsh impacts or jumps that can affect the wheel’s truing. While dirt biking can be thrilling, being mindful of the stress you put on your wheels can save you from the hassle of having to true them later. If you notice any major issues with truing, it’s best to seek professional help. They have the expertise to accurately assess and address wheel truing problems.

Frequently Asked Questions Of How To True A Dirt Bike Wheel

How Do You True A Dirt Bike Wheel?

To true a dirt bike wheel, start by securing the wheel on a truing stand. Use a spoke wrench to adjust the tension of each spoke, ensuring they are evenly tightened. Next, use a truing gauge to identify any wobbles or bends in the rim.

Gradually tighten or loosen the spokes to correct these imperfections until the wheel spins evenly.

What Tools Do I Need To True A Dirt Bike Wheel?

To true a dirt bike wheel, you will need a truing stand, a spoke wrench, and a truing gauge. The truing stand holds the wheel in place while you work on it, the spoke wrench allows you to tighten or loosen the spokes, and the truing gauge helps you identify any wobbles or bends in the rim accurately.

Why Should I True My Dirt Bike Wheel?

Truing your dirt bike wheel is crucial to maintain the performance and safety of your bike. A true wheel ensures smooth and stable rides, allowing for better control and handling. It also prevents unnecessary wear and tear on other components of the bike, such as the suspension system, brakes, and bearings.

Regularly truing your wheel can extend the lifespan of your dirt bike.

Conclusion

To ensure a smooth ride and optimal performance of your dirt bike, truing the wheel is essential. By following the step-by-step process mentioned in this blog post, you can master the art of truing dirt bike wheels. As one of the most crucial maintenance tasks, true wheels offer improved stability, balance, and control on uneven terrains.

Regularly inspect and true your dirt bike wheels to enhance your riding experience and prevent costly damages. So, gear up and give your dirt bike the true wheel treatment it deserves!