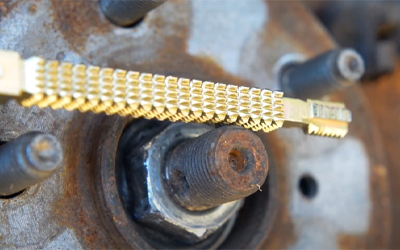

To fix a stripped thread, use a thread repair kit or insert a helicoil to restore the thread’s integrity. A stripped thread can be a frustrating problem, but fortunately, there are solutions available to fix it.

Whether you’re dealing with a stripped bolt hole, screw hole, or any other threaded opening, the key is to restore the thread’s functionality. One effective method is to use a thread repair kit, which typically includes tap and inserts specifically designed to repair stripped threads.

Another option is to insert a helicoil, a coiled wire insert, into the stripped hole to provide a new set of threads. Both of these solutions can help you avoid the need for more costly repairs or replacements. By knowing how to fix a stripped thread, you can save time and money while restoring the usability of your threaded components.

Credit: www.supercheapauto.com.au

What Causes A Stripped Thread?

Over-tightening: Over-tightening a bolt or screw can lead to a stripped thread. When excessive force is applied, it can cause the threads to wear down or deform, making it difficult to screw in or remove the fastener.

Cross-threading: Another common cause of stripped threads is cross-threading. This occurs when the bolt or screw is not properly aligned with the threaded hole and is forced into it. As a result, the threads become damaged and may no longer function properly.

Material fatigue: Thread stripping can also be caused by material fatigue. Over time, repeated stress or strain on the threads can weaken the material, causing it to wear down and eventually strip.

It is important to prevent stripped threads as they can lead to loose or improper assembly, causing potential problems or damage. To fix a stripped thread, options include using a thread repair kit, re-tapping the hole, or using an insert or helicoil to reinforce the threads.

How to Fix a Stripped Thread: Step by Step Guide

Identifying A Stripped Thread

Difficulty in screwing or unscrewing, looseness or wobbling of the fastened object, and visible signs of damage or wear are all indicators of a stripped thread. When a thread becomes stripped, it means that the grooves or ridges of the screw or bolt have worn down or become damaged, resulting in a weakened connection. This can occur due to over-tightening, improper threading, or simply wear and tear over time.

If you notice that screws or bolts are not securely fastened or are difficult to tighten or loosen, it’s important to address the issue promptly to avoid further damage or potential safety hazards. Inspect the fastened object for any visible signs of wear, such as flattened or rounded edges of the threads. Additionally, try using a different screw or bolt to see if the problem persists, as it may indicate a stripped thread.

Once a stripped thread is identified, there are various methods to fix the issue, such as using a thread repair kit or re-threading the hole with a tap and die set. It’s crucial to choose the appropriate method based on the severity of the damage and the type of materials involved. Taking immediate action to fix a stripped thread can help restore the integrity of the connection and ensure a secure fastening.

Solutions For Fixing A Stripped Thread

Using a tap and die set is a reliable option for fixing a stripped thread. It offers several advantages, including the ability to restore the original thread size and pitch, resulting in a strong and durable repair. The process involves several steps. First, you need to select the appropriate tap size and insert it into the tap wrench. Then, align the tap with the stripped thread and slowly rotate it clockwise. Apply cutting oil to facilitate the process and prevent further damage. Keep rotating until the tap reaches the desired depth. After cleaning the tap, switch to the die and repeat the process to create matching threads. Finally, check the repaired thread with a gauge to ensure its accuracy.

If using a tap and die set isn’t feasible, another option is to utilize thread inserts or helicoils. These inserts provide benefits such as creating new threads with excellent strength and durability. To install thread inserts or helicoils, start by drilling out the stripped hole using the recommended size of drill bit. Then, use a tap to create new threads inside the hole. Insert the helicoil into the newly created threads, ensuring it is flush with the surface. Lastly, use the provided installation tool to set the helicoil in place. This method guarantees a reliable solution for stripped threads.

Using epoxy or adhesive is an alternative option for thread repair. However, it comes with both pros and cons. While it offers convenience and ease of use, the strength of the repaired thread may not be as robust as when using tap and die sets or thread inserts. To repair the stripped thread using epoxy or adhesive, start by cleaning the area around the damaged thread thoroughly. Apply the adhesive or epoxy to the stripped area, ensuring sufficient coverage. Allow it to cure according to the manufacturer’s instructions. Once cured, the thread should be ready for use.

Tips For Preventing Stripped Threads

Proper torqueing and tightening techniques are crucial for preventing stripped threads. **Applying the correct amount of force** when tightening bolts and screws can help avoid excessive stress on the threads. **Using a torque wrench** is recommended to ensure precise tightening within the manufacturer’s specified range.

Lubrication can also aid in preventing stripped threads. Applying a lubricant to the threads before tightening can reduce friction and make threading easier. **Using an appropriate lubricant**, such as a thread sealant or anti-seize compound, can help protect the threads from damage.

Regular maintenance and inspections are essential for preventing stripped threads. Inspecting the threads periodically for signs of wear, corrosion, or damage can help identify potential issues before they worsen. **Replacing worn or damaged fasteners** promptly is necessary to prevent thread stripping.

Frequently Asked Questions Of How To Fix A Stripped Thread

How Do You Fix A Stripped Thread?

To fix a stripped thread, you can try using a thread repair kit or a helicoil. First, clean the area around the stripped thread. Then, insert the repair kit or helicoil into the hole and twist it in. This will provide a new thread for your bolt or screw to grip onto, fixing the issue.

What Causes A Thread To Become Stripped?

A stripped thread can be caused by various factors, including overtightening, incorrect threading, or using the wrong size or type of fastener. When a thread becomes stripped, it loses its ability to securely hold a bolt or screw in place.

This can lead to loose connections or even equipment failure if not addressed.

Can A Stripped Thread Be Repaired?

Yes, a stripped thread can be repaired. One common method is using a thread repair kit, which includes tools and inserts to create a new thread for the fastener. Another option is using a helicoil, which is a coiled wire insert that reinforces the stripped threads.

These solutions can restore the integrity of the thread and enable a secure connection.

Conclusion

Fixing a stripped thread doesn’t have to be a daunting task. By carefully following the steps outlined in this guide, you can confidently tackle this common issue yourself. Remember to start by identifying the problem, gathering the necessary tools, and using the appropriate techniques.

Taking the time to fix a stripped thread will not only save you money on repairs but also ensure the longevity of your equipment. Happy fixing!