A dirt bike engine works by burning a mixture of fuel and air to create power through combustion. Dirt bikes have small, lightweight engines that are designed to provide maximum power and efficiency for off-road riding.

These engines typically use a two-stroke or four-stroke design. In a two-stroke engine, the combustion process occurs in just one revolution of the engine’s crankshaft. This design allows for higher power output but can also be more polluting. On the other hand, four-stroke engines have a dedicated intake and exhaust stroke, which makes them more fuel-efficient and environmentally friendly.

Regardless of the design, dirt bike engines rely on spark plugs to ignite the fuel mixture, powering the bike and propelling it forward. Understanding how a dirt bike engine works is essential for riders to optimize performance and ensure proper maintenance.

Credit: m.youtube.com

How a Dirt Bike Engine Works: Step by Step Guide

The Basics Of Dirt Bike Engines

Dirt bikes are thrilling machines that offer an exhilarating off-road riding experience. At the heart of these powerful vehicles lies the engine, a complex system responsible for generating the necessary power to propel the dirt bike forward. In this article, we will explore the basics of dirt bike engines, including the various parts that make up the engine, the role of fuel and air in the combustion process, and the significance of the ignition system.

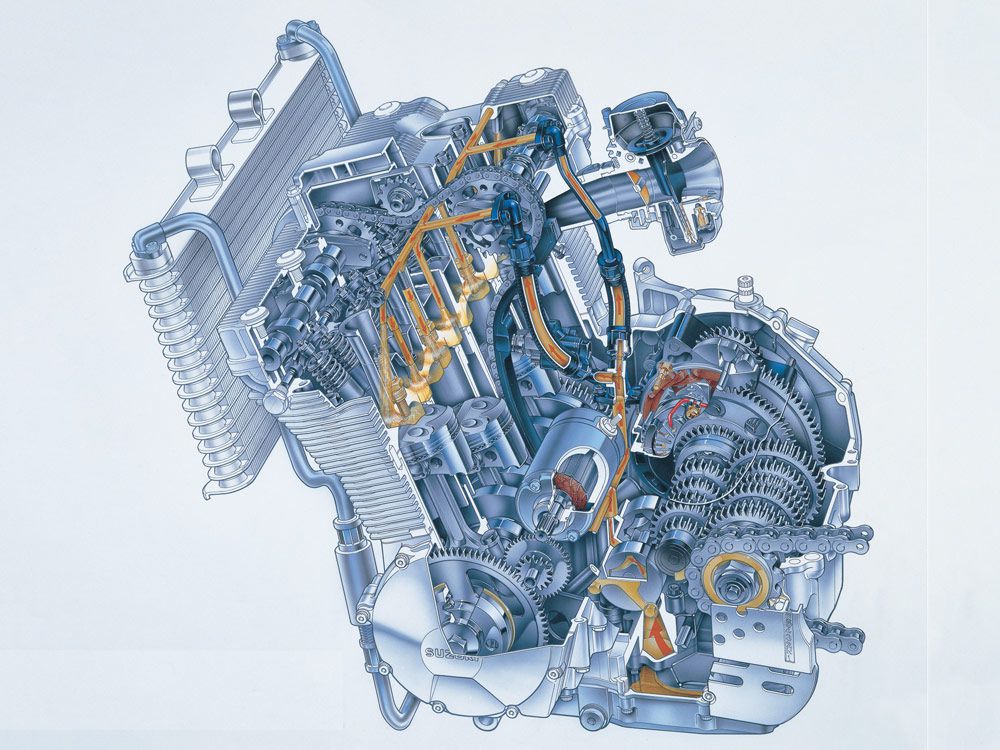

Parts of a Dirt Bike Engine

A dirt bike engine consists of several crucial components that work harmoniously to produce power. Understanding these parts is essential for anyone interested in the mechanics of dirt bikes.

1. Cylinder: The cylinder forms the main structure of the engine and houses the reciprocating piston.

2. Piston: The piston moves up and down inside the cylinder, converting the force generated by the combustion process into mechanical energy.

3. Crankshaft: The crankshaft connects the piston to the transmission system, transferring the reciprocating motion of the piston into rotational motion.

4. Camshaft: The camshaft controls the opening and closing of the valves, regulating the intake and exhaust process.

5. Valves: Dirt bike engines typically have two types of valves, intake valves, and exhaust valves. The intake valves allow the fuel-air mixture to enter the cylinder, while the exhaust valves release the combustion gases.

6. Spark Plug: The spark plug initiates the combustion process by creating a spark that ignites the fuel-air mixture.

7. Carburetor or Fuel Injection System: Depending on the type of dirt bike, it may be equipped with either a carburetor or a fuel injection system. These components are responsible for mixing the fuel with the incoming air to create the combustible mixture.

The Role of Fuel and Air in the Combustion Process

The combustion process is at the core of any engine, including dirt bike engines. To understand how a dirt bike engine operates, it is crucial to grasp the significance of fuel and air in this process.

Fuel and air are mixed together in the carburetor or fuel injection system, creating a combustible mixture. The air is drawn into the engine through the air filter, while fuel is introduced according to the throttle position. The ratio of fuel to air is carefully calibrated to achieve optimal combustion efficiency.

Once the fuel-air mixture enters the cylinder through the intake valves, it is compressed by the upward motion of the piston. As the piston reaches the top of its stroke, the spark plug creates a spark that ignites the compressed mixture. This combustion results in a rapid expansion of gases, generating high pressure.

The force produced by this rapid expansion of gases forces the piston downward, and the crankshaft converts this linear motion into rotational motion, which is then transferred to the transmission system. This process repeats itself thousands of times per minute, providing the power necessary to drive the dirt bike.

Understanding the Ignition System

The ignition system plays a vital role in ensuring the timely ignition of the fuel-air mixture inside the engine. It consists of several components, including the spark plug, ignition coil, and CDI (Capacitor Discharge Ignition) unit.

When the engine is running, the CDI unit receives a signal from the engine’s control unit, which determines the timing and intensity of the spark. The ignition coil amplifies this electrical signal and sends it to the spark plug, where the spark is produced to ignite the fuel-air mixture.

A well-functioning ignition system is crucial for optimal engine performance and efficient combustion. Regular maintenance and inspection of the spark plug and ignition components are necessary to ensure reliable operation and maximum power output.

In conclusion, understanding the basics of dirt bike engines empowers riders and enthusiasts to appreciate the intricacies underlying these powerful machines. From the various engine parts to the role of fuel and air in the combustion process, and the significance of the ignition system, each component contributes to the thrilling experience of tearing through off-road terrains on a dirt bike. As riders, it is essential to prioritize regular maintenance and care for the engine, ensuring its longevity and consistent performance.

An Inside Look At Dirt Bike Pistons

When it comes to the heart of a dirt bike engine, the piston plays a crucial role in the overall performance and power delivery. Serving as a key component of the engine’s combustion process, the piston undergoes immense heat, pressure, and mechanical stress as it moves up and down within the cylinder. In this article, we will take a closer look at the functions and importance of the piston, explore the differences between two-stroke and four-stroke pistons, and delve into the materials used in piston construction.

Functions and Importance of the Piston

The piston in a dirt bike engine serves multiple functions that are vital to its operation. Here are some of the key roles played by the piston:

- Intake and Compression: As the piston moves downwards, it creates a vacuum that allows the fuel-air mixture to enter the cylinder during the intake stroke. Once the mixture is inside, the upward movement of the piston compresses it, preparing for the combustion process.

- Combustion and Power: When the spark plug ignites the compressed fuel-air mixture, a controlled explosion occurs, generating high pressure and temperature. This rapid expansion drives the piston downward, converting the pressure into mechanical power.

- Exhaust: As the piston reaches the bottom of its stroke, it begins to move back up, pushing the spent exhaust gases out of the cylinder through the exhaust port. This process is known as the exhaust stroke.

In conclusion, the piston’s functions are vital to converting the energy from combustion into the mechanical power that propels the bike forward.

Differences Between Two-Stroke and Four-Stroke Pistons

Two-stroke and four-stroke engines utilize different types of pistons due to their distinct operating principles. Here’s a comparison of the two:

| Two-Stroke Piston | Four-Stroke Piston |

|---|---|

| Operates on a power stroke for every revolution of the crankshaft. | Operates on a power stroke every other revolution of the crankshaft. |

| Requires ports in the cylinder wall for intake and exhaust. | Uses valves for intake and exhaust, located in the cylinder head. |

| Transfers fresh fuel-air mixture through ports cut into the piston skirts. | Intake and exhaust valves are responsible for controlling the flow of fuel and air. |

| Lighter weight and simpler design with fewer moving parts. | Heavier and more complex design due to the presence of valves and associated components. |

Moreover, understanding these differences is essential for both riders and technicians while servicing and maintaining dirt bikes with either two-stroke or four-stroke engines.

Materials Used in Piston Construction

Pistons must be made from materials that can withstand the extreme conditions faced within the engine. The most commonly used materials for dirt bike pistons are:

- Aluminum: Due to its lightweight, high strength, and excellent heat dissipation properties, aluminum is the preferred choice for most dirt bike pistons. Additionally, aluminum allows for tighter tolerances, ensuring better performance and reduced friction.

- Forged Aluminum Alloy: For high-performance applications, pistons are often manufactured using a forged aluminum alloy. This process increases durability and strength, allowing the piston to withstand higher RPMs and greater stress.

In summary, the selection of appropriate piston materials is crucial for achieving optimal performance and reliability in a dirt bike engine.

Fuel Delivery Systems For Dirt Bikes

When it comes to dirt bikes, the fuel delivery system plays a crucial role in ensuring optimal performance and power delivery. Two common fuel delivery systems used in dirt bikes are carburetors and fuel injection systems. In this section, we will provide an overview of both systems and delve into how carburetors work in delivering fuel. Furthermore, we will also discuss the advantages and disadvantages of fuel injection systems.

Overview of carburetors and fuel injection systems

Before diving into the inner workings of carburetors and fuel injection systems, let’s briefly understand what each system entails.

A carburetor is a mechanical device responsible for mixing air and fuel in the correct ratio before delivering it to the engine. It consists of several components such as a venturi, throttle valve, float chamber, and jets. On the other hand, a fuel injection system uses electronic components to precisely control the amount of fuel injected into the engine.

How carburetors work in delivering fuel

Carburetors are commonly used in older dirt bike models and have been the go-to fuel delivery system for many years. Their simplicity and reliability make them popular among riders and mechanics. Let’s take a closer look at how carburetors work in delivering fuel.

Carburetors operate based on the principle of Bernoulli’s equation, which states that as the airspeed increases, the pressure decreases. When the rider opens the throttle, air rushes through the venturi, creating a low-pressure area. This low-pressure region pulls fuel from the float chamber through the jets, mixing it with the incoming air. The resulting mixture is then delivered to the engine for combustion and power generation.

Overall, carburetors provide a simple and cost-effective solution for fuel delivery. However, they may require regular tuning and adjustment to maintain optimum performance, especially in varying weather conditions or at different altitudes.

Advantages and disadvantages of fuel injection systems

In recent years, fuel injection systems have gained popularity due to their precise fuel control and improved efficiency. Let’s explore the advantages and disadvantages associated with fuel injection systems.

Advantages:

- Fuel injection systems offer precise fuel control, allowing for optimum air-fuel mixture under various riding conditions.

- They provide better fuel efficiency and throttle response compared to carburetors, resulting in improved performance.

- Modern fuel injection systems can adjust fuel delivery in real-time, adapting to changing environmental factors and rider demands.

Disadvantages:

- Fuel injection systems are generally more complex and expensive compared to carburetors, increasing the initial cost of a dirt bike.

- They require specialized tools and knowledge for maintenance and troubleshooting.

It is important to note that while fuel injection systems offer several advantages, carburetors still hold their ground in many dirt bike applications due to their simplicity and proven reliability.

Engine Lubrication And Cooling

When it comes to the performance and longevity of a dirt bike engine, proper lubrication and cooling are of utmost importance. Without adequate lubrication, the moving parts of the engine would experience excessive friction and wear, leading to decreased performance and potential damage. Similarly, inadequate cooling can cause the engine to overheat, resulting in a loss of power and possible engine failure. In this section, we will explore the importance of lubrication in engine performance, the types of engine oils used in dirt bikes, and strategies for cooling the engine.

Importance of lubrication in engine performance

Lubrication plays a crucial role in the overall performance of a dirt bike engine. Its primary function is to reduce friction between the moving parts, such as the pistons, cylinders, and connecting rods. By creating a thin layer of lubricating oil between these parts, frictional heat is minimized, preventing excessive wear and tear. This allows the engine to operate smoothly and efficiently, maximizing power output and extending the engine’s lifespan.

Types of engine oils used in dirt bikes

Choosing the right engine oil for your dirt bike is essential for optimum performance. There are various types of engine oils available, each formulated to meet specific requirements. Some common types include:

- Mineral oils: These oils are derived from crude oil and offer basic lubrication properties. They are suitable for older dirt bike engines or those operating under normal conditions.

- Synthetic oils: Synthetic oils are artificially created using a complex chemical process. They provide superior lubrication and can withstand extreme temperatures, making them ideal for high-performance dirt bike engines.

- Semi-synthetic oils: As the name suggests, these oils are a blend of mineral and synthetic oils. They offer a balance between affordability and performance, making them a popular choice for many dirt bike enthusiasts.

It is crucial to consult your dirt bike’s manufacturer or refer to the owner’s manual to determine the recommended oil type and viscosity for your specific engine.

Strategies for cooling the engine

In addition to lubrication, effective cooling is vital to prevent the engine from overheating. This is especially crucial during intense riding sessions or in hot weather conditions. Here are some strategies for cooling the dirt bike engine:

- Air cooling: Many dirt bikes utilize air cooling, where the engine is exposed to moving air to dissipate heat. This is achieved through strategically placed cooling fins, which increase the surface area and facilitate heat transfer.

- Liquid cooling: Liquid cooling systems, on the other hand, use a coolant fluid circulated through the engine to absorb and transfer heat. The coolant is cooled by a radiator and fan, preventing the engine from reaching critical temperatures.

- Regular maintenance: Keeping the air filters clean and changing the coolant regularly are essential maintenance tasks to ensure efficient engine cooling. Clogged air filters restrict airflow, while old coolant loses its effectiveness in dissipating heat.

- Avoiding prolonged idling: Allowing a dirt bike engine to idle for extended periods can lead to inadequate cooling. When not in use, it is best to turn off the engine to prevent unnecessary heat buildup.

By adhering to these cooling strategies and using appropriate lubrication, you can optimize the performance and reliability of your dirt bike engine.

The Role Of The Exhaust System

How exhaust systems work in dirt bikes

The exhaust system plays a crucial role in the performance of a dirt bike engine. It is responsible for carrying out the waste gases produced during the combustion process and plays a significant role in optimizing the overall engine performance.

The exhaust system in a dirt bike consists of several components, including the exhaust header, the muffler, and the tailpipe. Each component works together to ensure the smooth flow of exhaust gases and to minimize any restrictions that could impede the engine’s performance.

The exhaust header is the primary component where the exhaust gases are released from the engine’s combustion chamber. It is designed specifically to enhance the scavenging effect, which helps in improving the engine’s performance by effectively removing the burnt gases and maximizing the intake of the fresh air-fuel mixture.

Benefits of an efficient exhaust system

An efficient exhaust system offers several benefits to dirt bike riders:

- Improved engine performance: A well-designed exhaust system allows better expulsion of exhaust gases, resulting in improved engine efficiency and increased power output.

- Enhanced throttle response: An efficient exhaust system helps to reduce backpressure, allowing the engine to breathe more freely. This results in improved throttle response, allowing riders to accelerate more quickly and smoothly.

- Weight reduction: Upgrading to a high-performance exhaust system can often result in weight reduction, which can improve the bike’s overall handling and maneuverability.

- Enhanced sound: A quality exhaust system can also provide a distinctive and satisfying exhaust note, adding to the overall riding experience.

Exhaust system modifications for improved performance

Many dirt bike enthusiasts opt for modifications to their exhaust systems to further enhance their bike’s performance. Some popular modifications include:

- Aftermarket exhaust systems: Upgrading to an aftermarket exhaust system can provide substantial gains in performance. These systems are designed with larger-diameter pipes, improved airflow, and often weigh less than stock exhaust systems.

- Tuning the exhaust: Adjusting the length and diameter of the exhaust pipes can fine-tune the power delivery of the engine, optimizing performance at specific RPM ranges.

- Exhaust system heat wrapping: Heat wrapping the exhaust system can help to reduce heat loss and improve exhaust gas velocity, resulting in increased power and torque.

- Removing or replacing the muffler: Modifying or replacing the muffler can reduce weight, improve sound, and potentially increase exhaust flow for enhanced performance.

Remember, when considering modifications to the exhaust system, it’s important to consult with a knowledgeable mechanic or experienced professional who can guide you in choosing the right modifications for your specific needs and riding style.

Transmission Systems In Dirt Bikes

One of the most crucial components in a dirt bike is its transmission system. This system is responsible for transferring power from the engine to the wheels, ensuring the bike can shift gears smoothly and efficiently. In this blog post, we will take a closer look at the transmission system in dirt bikes, focusing on the functions of the clutch, gears, and drive chain, as well as how power is transferred to the wheels.

Overview of the Transmission System

The transmission system in dirt bikes consists of several key components that work together to ensure seamless power transfer. These components include the clutch, gears, and drive chain. Understanding how each element functions is essential to comprehend the overall operation of the transmission system.

Functions of the Clutch, Gears, and Drive Chain

Let’s break down the functions of each component:

Clutch

The clutch is responsible for engaging and disengaging the engine power from the transmission. When the clutch lever is pulled in, it releases the pressure on the clutch plates, allowing the rider to shift gears without causing any damage to the transmission. Upon releasing the clutch lever, the plates engage, providing power to the transmission system.

Gears

Gears play a vital role in controlling the speed and torque output of the bike. By shifting gears, riders can adjust the engine’s RPM (revolutions per minute) to match different riding conditions. Lower gears provide more torque for climbing steep terrains, while higher gears allow for increased speed on straightaways. Gear shifting is accomplished by using the gear shifter and clutch lever in combination.

Drive Chain

The drive chain transfers power from the transmission to the rear wheel, propelling the bike forward. It consists of a series of interconnected links and sprockets. As the transmission output shaft rotates, it drives the front sprocket, which, in turn, rotates the drive chain. This rotational force is then transferred to the rear sprocket, causing the rear wheel to spin.

How the Transmission Transfers Power to the Wheels

Now that we understand the functions of the clutch, gears, and drive chain, let’s dive into how power is transferred to the wheels in a dirt bike:

- The engine produces power by burning fuel and air within the combustion chamber.

- The clutch disengages the engine power from the transmission system while shifting gears.

- The rider selects the desired gear by using the gear shifter and clutch lever.

- As the clutch lever is released, the clutch plates engage, transmitting engine power to the transmission.

- The transmission uses a system of gears to adjust the engine’s RPM and torque output.

- The rotational force is transferred from the transmission to the drive chain via the front sprocket.

- Finally, the power is transferred from the drive chain to the rear wheel through the rear sprocket, propelling the bike forward.

By understanding how the transmission system operates, riders can make informed decisions when shifting gears and maximize the performance of their dirt bikes.

Maintenance And Troubleshooting Tips

Regular maintenance plays a crucial role in keeping your dirt bike engine running smoothly. By implementing proper care and troubleshooting techniques, you can prevent costly repairs and ensure your bike performs at its best. In this section, we will explore some essential maintenance practices, common issues, and troubleshooting tips that every dirt bike owner should know.

Regular maintenance practices for dirt bike engines

Regular maintenance practices are essential for the longevity and optimal performance of your dirt bike engine. By following these simple routines, you can keep your engine running smoothly:

- Oil changes: Regularly changing the oil in your dirt bike engine is crucial to keep it operating efficiently. This helps remove debris, contaminants, and moisture that could cause damage.

- Air filter cleaning: Cleaning or replacing the air filter regularly is essential to ensure proper air intake and prevent dirt and debris from entering the engine.

- Spark plug inspection: Regularly inspecting and cleaning the spark plug helps maintain proper ignition and prevent misfires.

- Chain and sprocket maintenance: Keeping the chain properly lubricated and tensioned will enhance performance and prevent premature wear.

- Checking fluid levels: Regularly inspecting and topping off coolant, brake fluid, and other fluids is crucial to prevent overheating and ensure optimal performance.

Common issues and troubleshooting techniques

Even with regular maintenance, dirt bike engines may encounter common issues. Here are some common problems you may encounter, along with troubleshooting techniques:

| Common Issue | Troubleshooting Technique |

|---|---|

| Difficulty starting the engine | Check the spark plug, fuel mixture, and fuel system for any clogs or issues. Ensure that the choke is properly engaged. |

| Excessive engine noise | Inspect the exhaust system for any leaks or loose components. Tighten or replace any faulty parts. |

| Poor engine performance or stalling | Inspect the air filter, fuel delivery system, and carburetor for any clogs or issues. Clean or replace components as necessary. |

| Overheating | Check the coolant levels and ensure that the cooling system is free from leaks or obstructions. Consider cleaning or replacing the radiator if necessary. |

Importance of proper maintenance in prolonging engine lifespan

Proper maintenance is paramount when it comes to extending the lifespan of your dirt bike engine. Regular maintenance not only prevents issues and breakdowns but also ensures that your engine operates at its peak performance. By adhering to routine maintenance practices, you can prevent premature wear, enhance fuel efficiency, and enjoy a longer-lasting engine.

Now that you have a better understanding of the importance of maintenance and troubleshooting tips, you can take the necessary steps to keep your dirt bike engine in top shape. Implementing regular maintenance practices and addressing common issues promptly will ensure a longer lifespan for your engine and countless hours of thrilling rides.

Enhancing Dirt Bike Engine Performance

Upgrades and modifications for improved performance

If you’re a dirt bike enthusiast looking to take your riding experience to the next level, enhancing the performance of your dirt bike engine is key. By making upgrades and modifications to your engine, you can unleash its true potential and enjoy a more powerful and thrilling ride. Whether you’re a seasoned rider or a beginner, there are several upgrades and modifications you can consider to improve the performance of your dirt bike engine.

Importance of tuning and jetting the engine

Tuning and jetting the engine of your dirt bike is an essential step towards optimizing its performance. Tuning involves adjusting various engine components to achieve the perfect balance between power and reliability. Jetting, on the other hand, refers to the process of fine-tuning the fuel-to-air mixture for optimal combustion.

By ensuring the engine is properly tuned and jetted, you can experience improved throttle response, increased power output, and smoother acceleration. Therefore, paying attention to the tuning and jetting of your engine is crucial for maximizing its performance.

Considerations for choosing aftermarket parts

When it comes to enhancing your dirt bike engine’s performance, choosing the right aftermarket parts is crucial. Aftermarket parts are designed to replace the stock components of your engine, offering improved performance, durability, and customization options. However, with a plethora of aftermarket parts available in the market, it’s important to consider a few factors before making a purchase.

***Some considerations include*** the reputation and reliability of the manufacturer, compatibility with your bike model, the specific performance gains you’re looking to achieve, and your personal budget. By carefully considering these factors, you can ensure that the aftermarket parts you choose will enhance your engine’s performance as desired.

Frequently Asked Questions For How A Dirt Bike Engine Works

How Does A 4-Stroke Dirt Bike Work?

A 4-stroke dirt bike works by combining fuel and air through four steps: intake, compression, combustion, and exhaust.

How Does A Bike Engine Work Step By Step?

A bike engine works by igniting fuel and creating small explosions, which are converted into mechanical energy to move the bike forward.

How Does A 4-Stroke Motorbike Engine Work?

A 4-stroke motorbike engine works by completing four steps: intake, compression, combustion, and exhaust.

How Does A 125Cc Engine Work?

A 125cc engine works by combining air and fuel inside the combustion chamber, which is then ignited by a spark plug to create a powerful force that drives the motorcycle forward.

Conclusion

To sum up, understanding how a dirt bike engine works is essential for any dirt bike enthusiast. By comprehending the four-stroke process, the intake, compression, power, and exhaust strokes, riders can better appreciate the inner workings of their bikes. The engine’s combustion chamber, valves, piston, crankshaft, and other components all play crucial roles in generating power and speed.

Regular maintenance, such as oil changes and air filter cleaning, will ensure optimal performance and longevity. Moreover, knowing how to troubleshoot common engine problems like fouled spark plugs or a flooded engine will save time and money. As you gain knowledge and experience with your dirt bike engine, you’ll have a deeper appreciation for the harmonious interaction of these components, fueling your passion for the thrilling world of dirt biking.

So, get out there and enjoy the exhilarating ride!